The Integrated MES Software of Fluentis ERP

Fill out the form to request information

Watch Video

Ricordati di accettare i cookie se vuoi vedere il video.

Key features of a MES

Inform the production departments of the activities to be carried out, with the possibility of releasing a detailed short-term production plan

Make all the necessary information for the execution of activities available in the department, such as operating instructions, setup sequences, workshop drawings, and specific customer requirements

Collect real-time information on ongoing activities (start of activity, break, end of activity distinguished by machinery and operators, accounting for quantities produced, and defective pieces with related identified defects)

Provide departmental analysis tools for efficiency and quality

Simplify the operator-system information interface, considering the peculiarities and limitations of the production environment

MES Software, an essential tool for manufacturing companies

In the production environment, having real-time data is crucial for making the right decisions. MES software, or Manufacturing Execution System, allows the management of production department activities in a simple and fast way, acquiring real-time data on quantities, times, production costs, and measuring the efficiency of production accordingly. Furthermore, MES helps avoid transcription errors because paper is eliminated, and data is automatically collected from machines.

It is a process that starts from planning and involves all business functions, from quality to warehouse, up to logistics. Therefore, it is important to have an MES natively integrated with other production support tools so that it contributes to substantially reducing the complexities already present in the company. Fluentis ERP is equipped with a natively integrated MES, capable of seamlessly interconnecting and exchanging information with various business departments.

MES Software and ERP: better if natively integrated

The MES system is highly interactive, connecting to many modules of an ERP system, i.e., many aspects of business management, with which it exchanges a lot of information, both receiving and producing it. In particular, in addition to the obvious connection to Production Planning and MRP, it can connect to the warehouse management system, sales, personnel management, logistics, cost control, and quality management.

Precisely because of these infinite possibilities of interaction with various business departments and the vast number of interrelationships that characterize it, the MES system must be a perfectly integrated product, preferably natively integrated, under penalty of many problems.

In particular, integrating an external product can lead to the following problems:

Data not updated in real-time but at predefined moments via batch processes;

Long integration time with the ERP system, resulting in high costs;

Difficulty in communication between providers of the two systems;

Periodic costs for updating to new versions of the ERP;

Risk of data unavailability due to communication problems/unforeseen errors."

What the Integrated MES of Fluentis can do

Fast and Simple Production Declarations with Bar-Codes

The procedure can recognize each workstation on which it is running.

If a work center has been associated with these, it will automatically load all the phases in progress on them. At that point, the operator can choose whether to continue with the declaration of these phases or enter new ones.

In production environments, operators often have little familiarity with keyboards or work in conditions that make their use difficult.

In the Fluentis MES, many input operations can be facilitated and accelerated by using a barcode field that, when appropriately configured, intelligently processes the acquired data and enters more information simultaneously with a single scan.

This provides a significant advantage to the operator in terms of data entry speed and efficiency, as they only need to read data in the same “barcode” field without having to change the field focus using the keyboard.

The “barcode” field in MES allows the operator to add individual phases or groups of phases or, for example, even the phases of an entire production order, or load the lots and/or serial numbers of materials to be consumed, all by simply reading their barcodes.

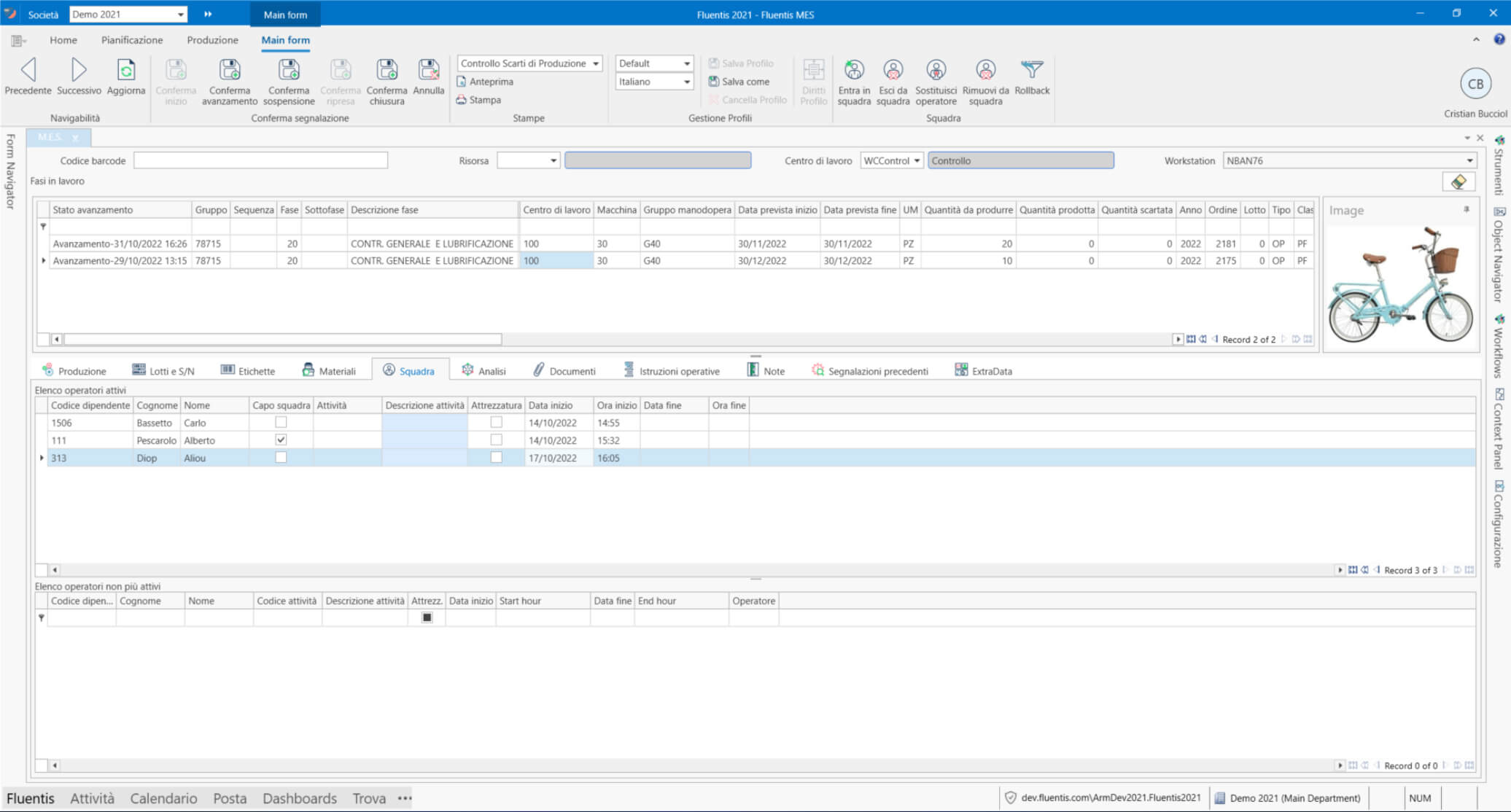

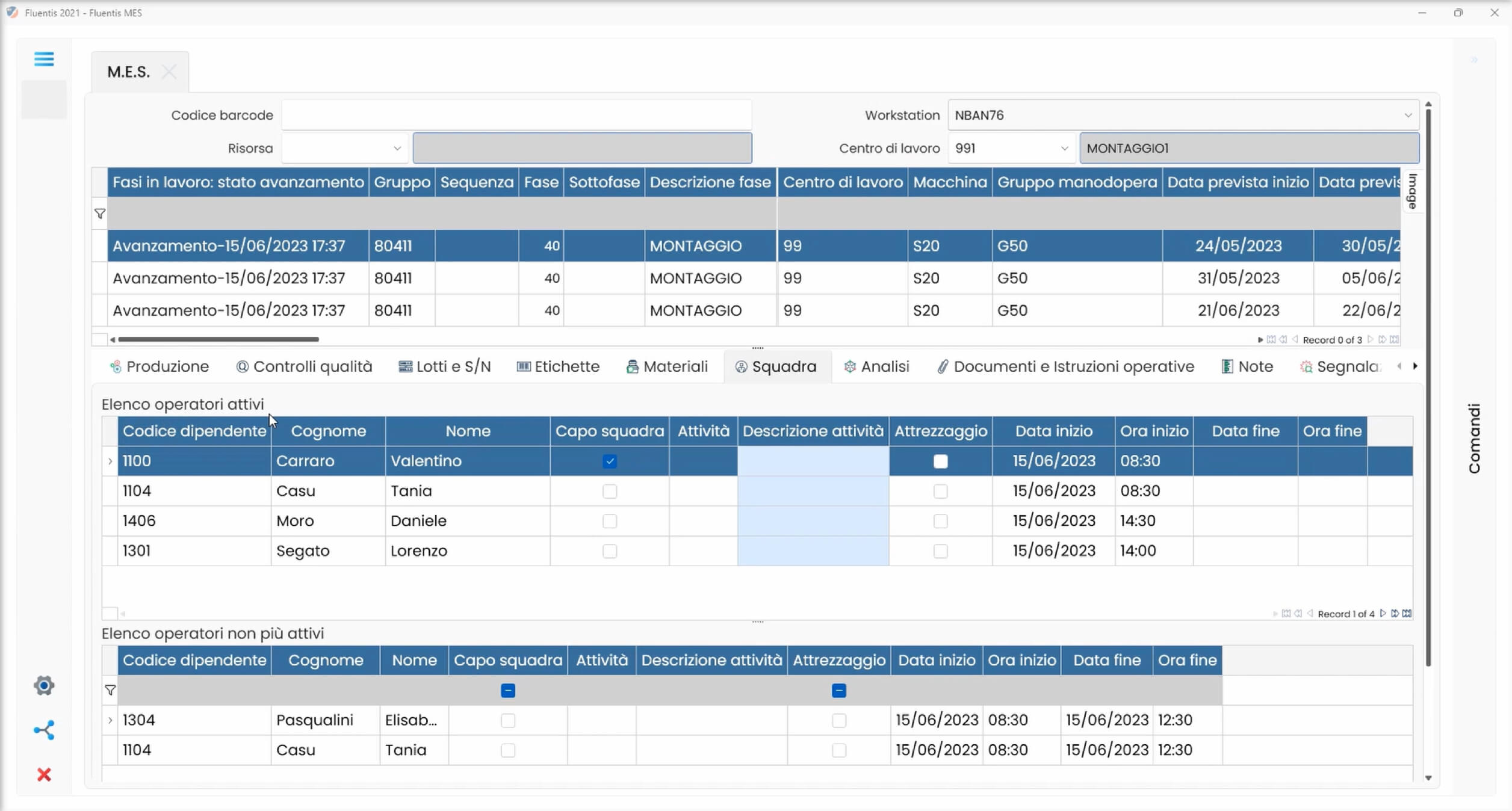

Work Team Management

During the finalization of a phase, it is possible to indicate the composition of the team carrying out the activity.

Operators can be brought into or out of the team, allowing for each to have their actual working time in that activity recorded. If the operator has a badge, through barcode reading, their entry and exit from the team can be recorded using the “barcode” field.

It is also possible to activate a cross-check with the entry and exit timestamps in the company, which can be used to verify the actual presence of the operator working at a specific work center.

In addition, if necessary, the operator can be required to register at that workstation by entering their username and/or password before starting to use MES.

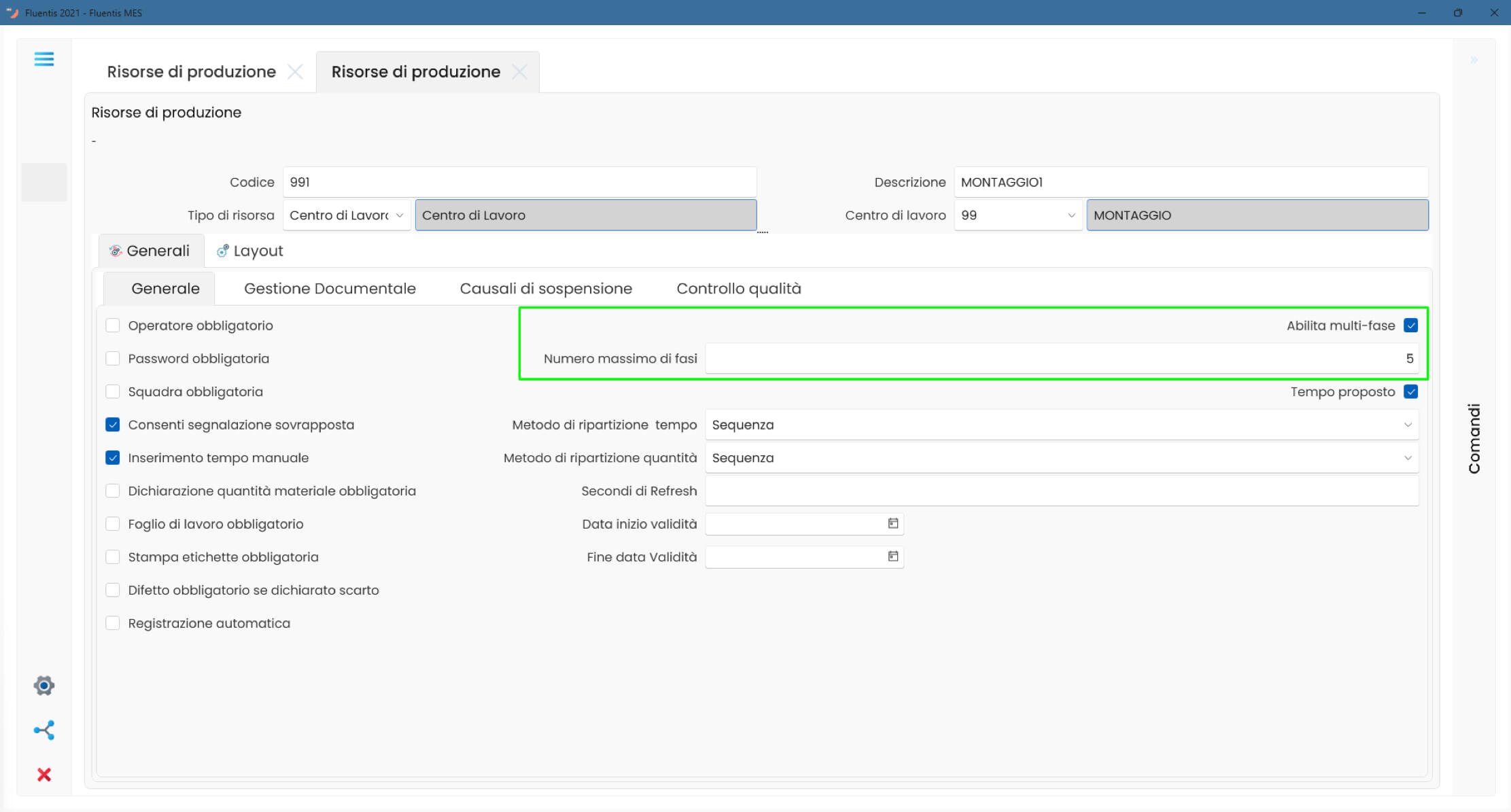

Simultaneous Declaration of Multiple Phases

For each work center, it is possible to set a series of parameters to customize its operation. For example, make that work center single-phase or multi-phase, indicating in this case also a maximum number of phases that can be executed simultaneously.

In the case of a multi-phase center, it is also possible to parameterize the ways in which quantities and times are reported.

These modes are:

- In sequence (the order in which the phases are);

- Proportional (times and quantities are attributed to individual phases in proportion to the quantities to be produced);

- Manual (the operator manually enters values for each phase).

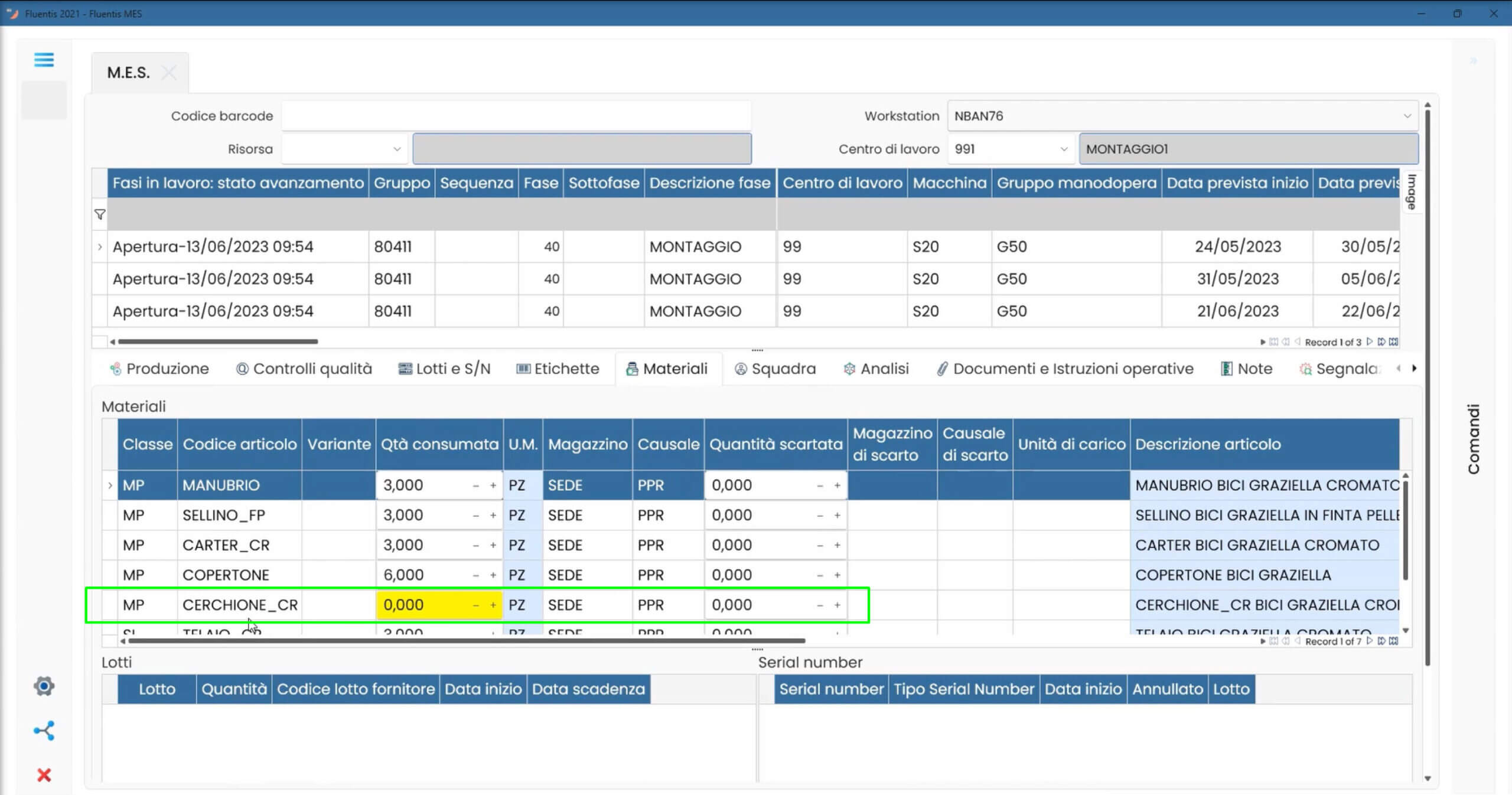

Material Flow Management

Regarding the unloading of materials during production, in MES, the consumption calculation is automatically based on the quantity to be produced and what is present in the bill of materials.

In cases where some materials are not indicated in the bill of materials or the quantity is only indicative (for example, if it cannot be definitively defined due to the yield of the production process), or different materials are used from those in the bill of materials, the operator can indicate the materials and quantities actually used.

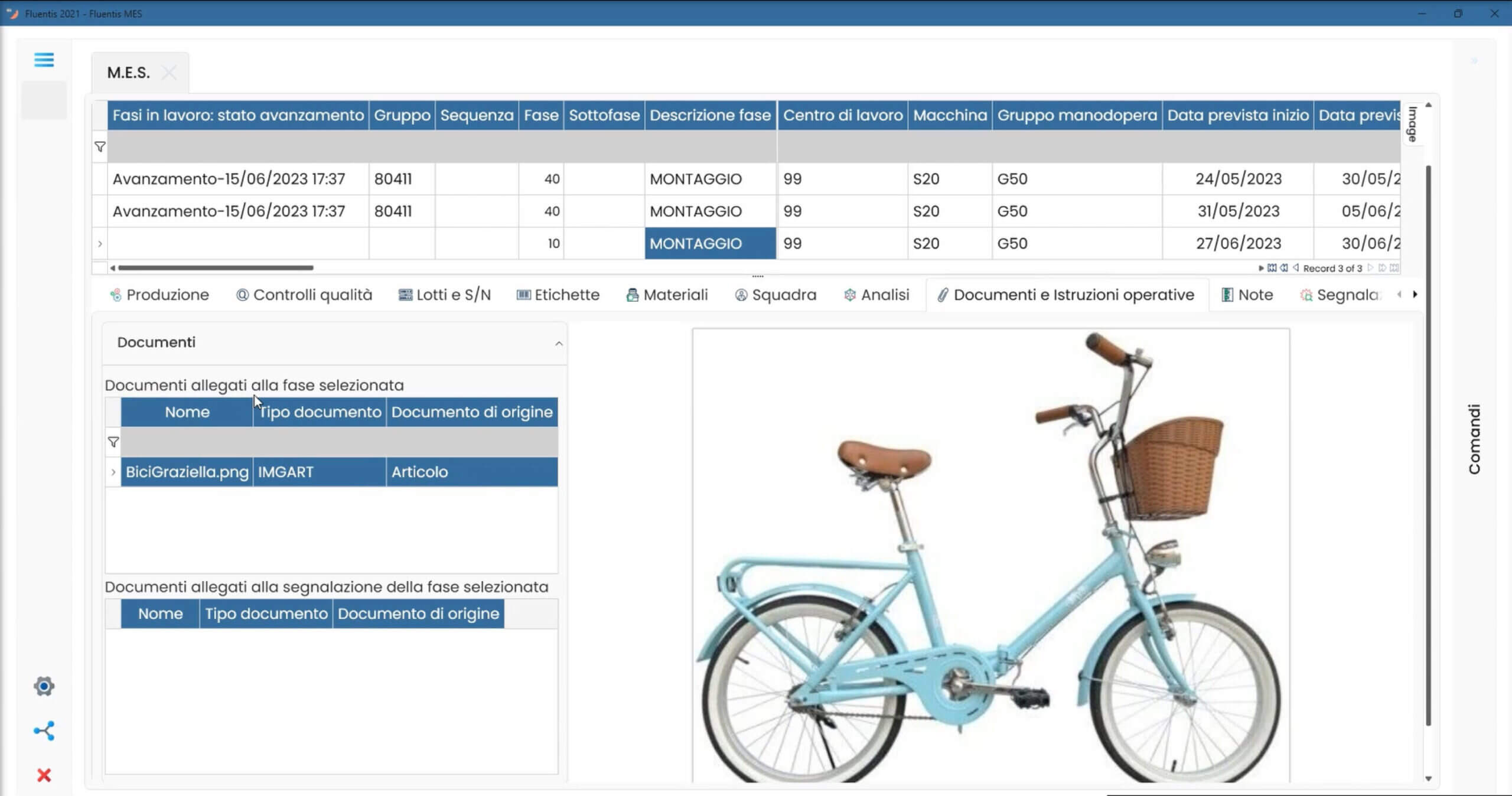

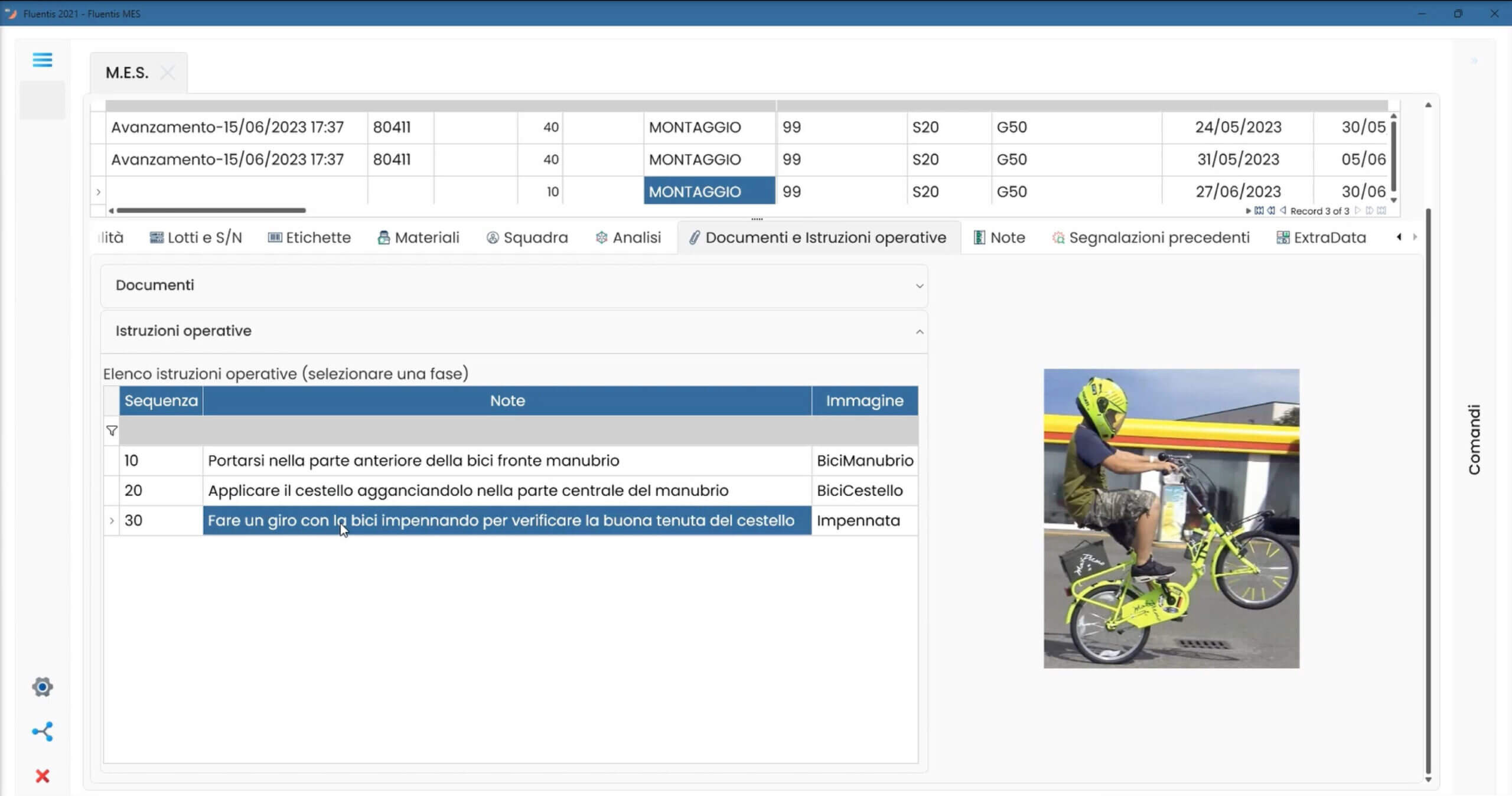

The Documentation Available at the Machine

Fluentis ERP has integrated Document Management with all other procedures, allowing for cataloging, archiving, and searching for every document with a simple click, using the BCR (Bar Code Recognition) functionality, which recognizes a document based on its associated barcode at the time of insertion into the repository.

These advantages also extend to MES, where it is possible to display, to production operators, all documents related to the article, customer order, job, and production order.

It is possible to attach documents directly to each completion in MES, even via drag & drop, such as production defects that will be subsequently used to open any non-conformities.

Furthermore, through the operating instructions, it is possible to provide the operator with a series of directives that are not only descriptive but also accompanied by images, making all documents related to individual phases of the work cycle available at the machine. This includes the ability to view instructions, technical drawings, assembly diagrams, etc., and even videos that will allow the operator to perform their work more precisely and punctually.

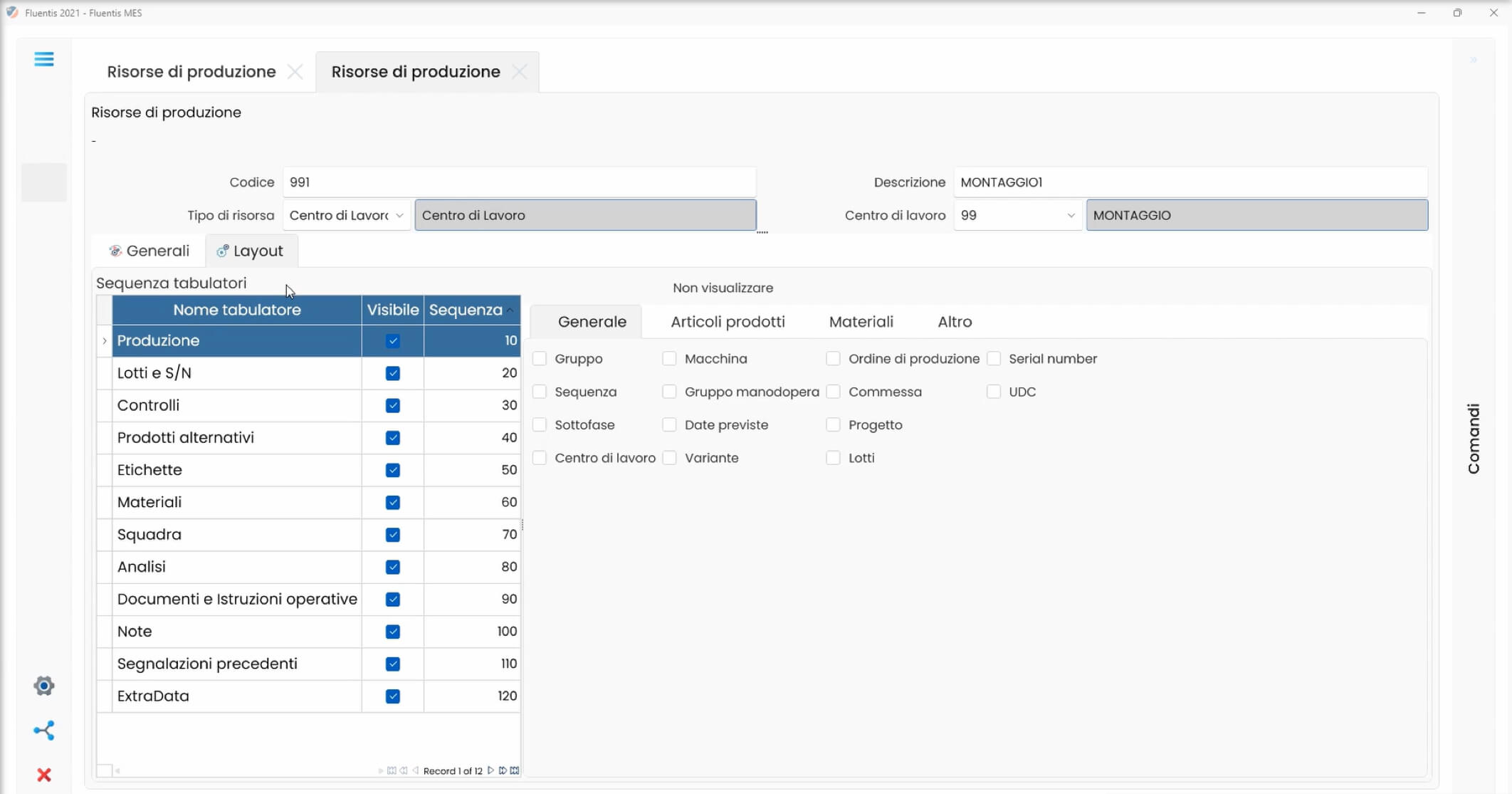

The Customization of Fluentis MES Features and Layout

Fluentis MES provides users with a variety of customizations at both the functional and layout levels. These customizations are at the level of individual work centers; therefore, each resource can work and present itself with a different layout based on specific needs.

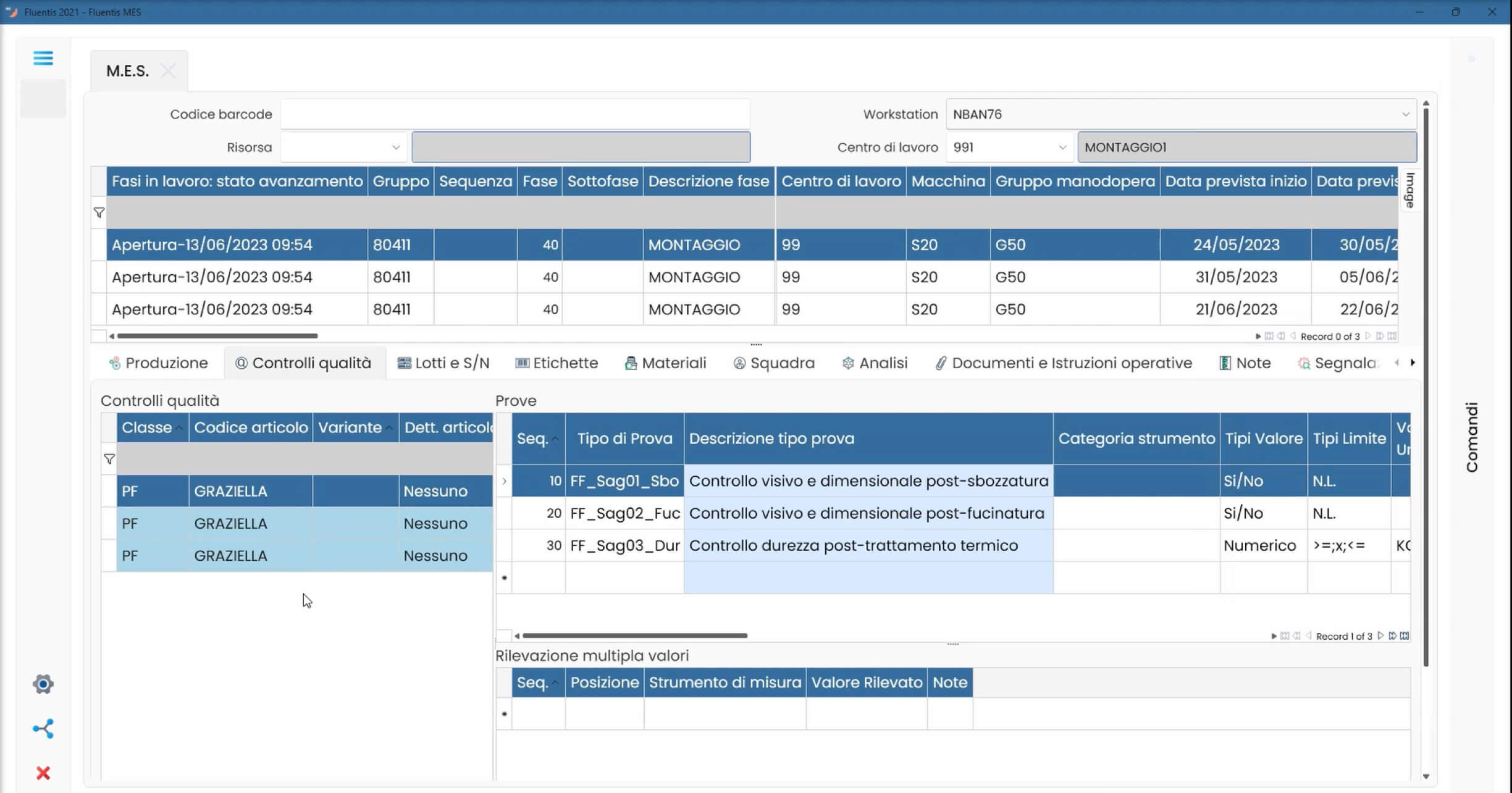

Integration with Quality Management

In Fluentis MES, Quality Management is natively integrated as an application area.

MES plays a prominent role in quality control processes.

It can manage and monitor constant monitoring activities of the production process, handle and detect final analysis and testing activities.

It can detect and alert on deviations that may affect the quality of what is produced.

In case of problems and disputes, Quality integrated with MES ensures traceability and can trace back to the affected production batch.

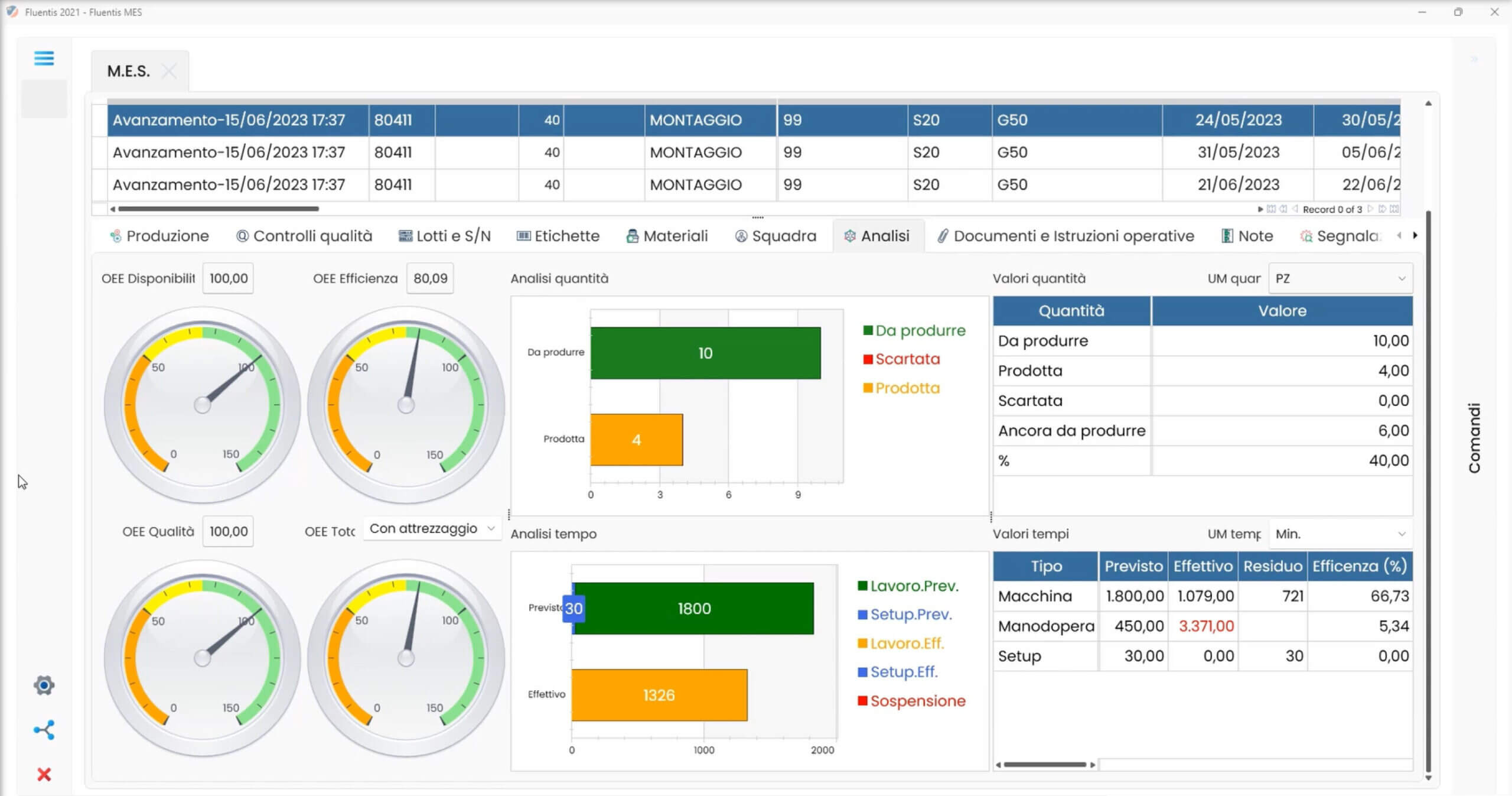

Monitoring of key production KPIs

Implementing MES software also facilitates the collection of information that determines performance, ensuring control over objective indicators that quantitatively measure the performance of a production system.

In Fluentis MES, it is possible to monitor the trends of key production KPIs such as OEE, Overall Equipment Effectiveness, which is a performance index to measure the performance of machinery in terms of availability, efficiency, and quality.

Discover what Fluentis can do

for your company

15-day free trial | No automatic renewal | Immediate access